这是附加信息

Shock is the enemy of a tourbillon movement. Richard Mille’s solution to this? Why, a cable-suspended movement! The atypical architecture of this design required the creation of two separate baseplates.

The first, or ‘peripheral’ plate, is fixed to the case and supports the tensioner mechanisms. The second, known as the ‘central’ plate, is linked to the peripheral plate by cables and incorporates the wheels comprising the calibre as well as the winding mechanism.

The central baseplate rests, like a spider in the middle of its web, on two braided steel cables just 0.27 mm in diameter. These cables, sketching a three-dimensional structure in their path through 10 pulleys, are anchored by 4 tensioners.

The watchmaker is responsible for tensioning the cables by rotating a spline screw located at the centre of each tensioner. By ensuring an even distribution of tension, this pulley system guarantees perfect balance of the whole mechanism

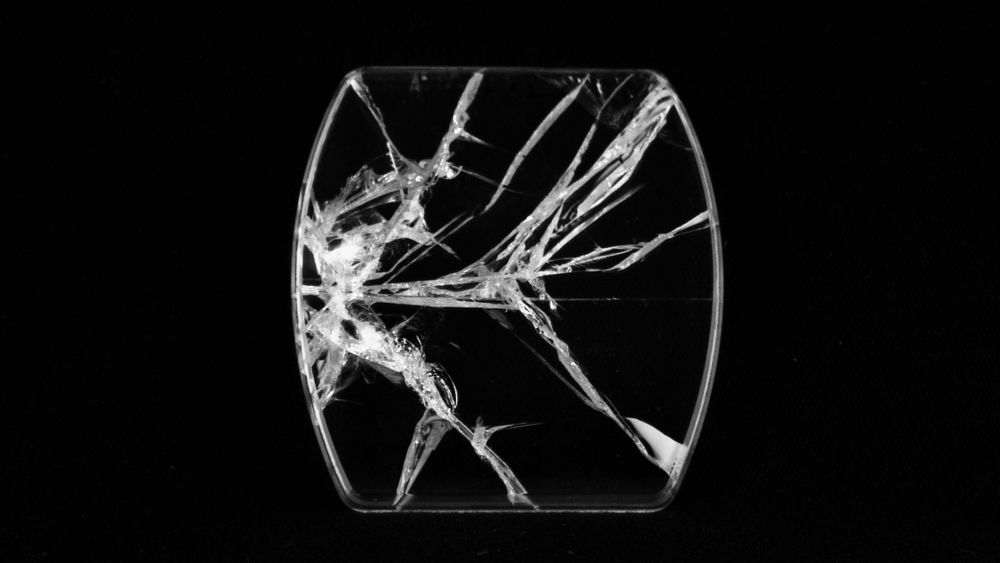

Well aware that regular glass would not provide the necessary resistance to ward off the impact of a mallet, engineers for the brand, collaborating with Stettler - a world-renowned sapphire specialist - took inspiration from current practices in the automotive realm to produce a laminated glass.

Use of this glass, composed of two sheets of sapphire glass separated by a thin Polyvinyl film, constitutes a horological first. In the face of the strong shockwave produced by a blow from a mallet, the glass will crack, but without ever shattering. With anti-reflective and UV coatings, this glass, which preserves the movement from the external environment, is a patent-pending Richard Mille exclusive.

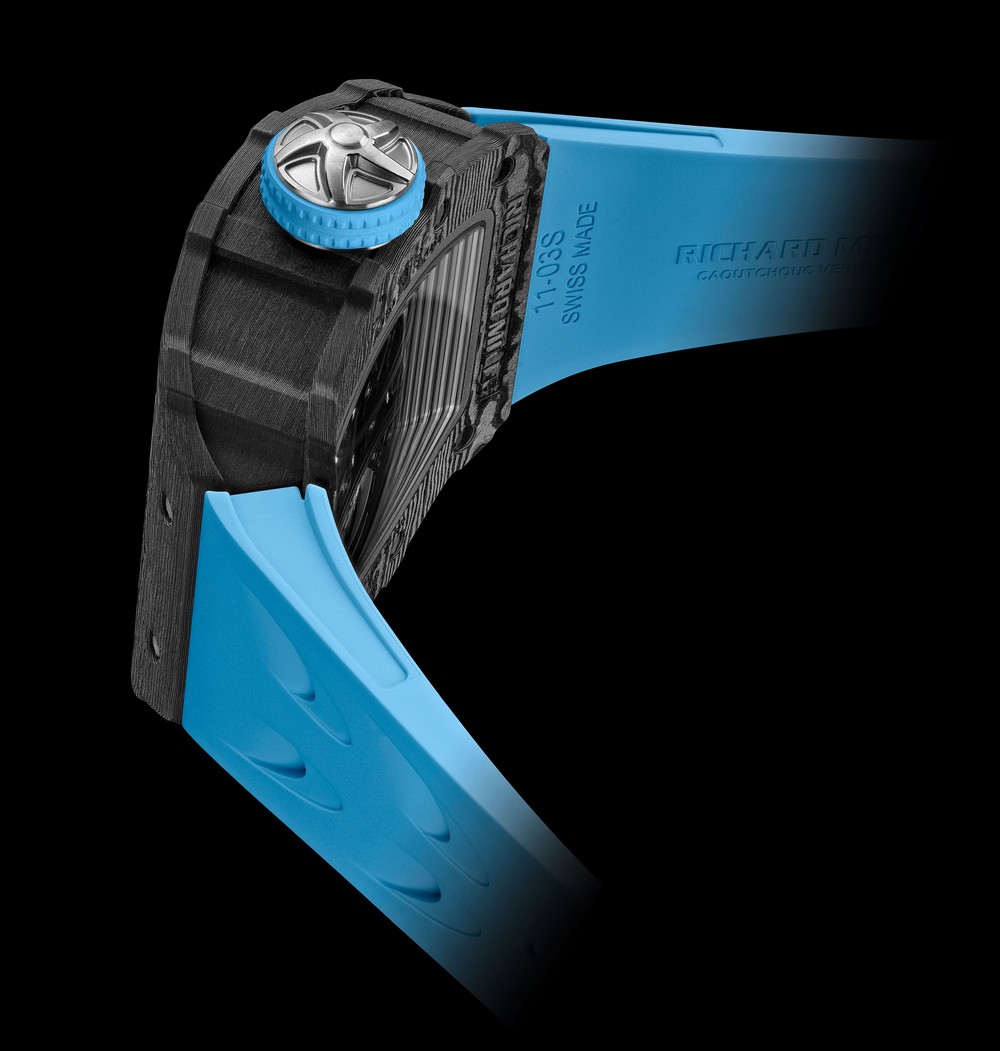

Punctuated by notches that reinforce its structural integrity, the case is machined in Carbon TPT®, a fabulously tough and virtually indestructible protection, recognised for its excellent resistance to micro-cracks and tears. The characteristic damascene sheen of Carbon TPT® and sharp lines of the

case speak to the especially sporty nature of this watch.